Project Date

June 2017

Project Scope

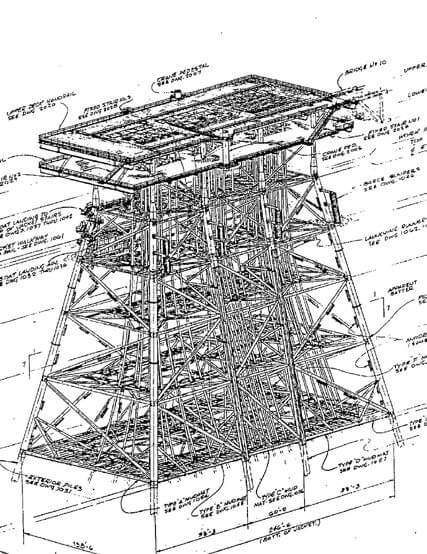

Hydra completed a multi-platform reconstruction project for major independent oil and gas operator, Freeport-McMoran. Contracted to complete topside preparations before plug and abandonment (P&A) crews could decommission the wells and remove the structures, Hydra renovated the platforms to comply with all Bureau of Safety and Environmental Enforcement (BSEE) regulations.

The deteriorating bridge and connecting platforms required heavy lift readiness (HLR) crews to eliminate hazards for the P&A crew. The project scope included:

- Restoration of grating, handrail systems and stairways

- Reconstruction of structural beams

- Removal and replacement of failing material

- Replacement of wooden deck boards

- Overall platform clean

- Trash removal for disposal

- Fabricate and install boat landings for emergency egress

- Rebuild well bays

- Closeout all BSEE Incidents of Non-Compliance (INCs)

- Install temporary housing quarters for P&A crews

Location & Project Details

- S. Gulf of Mexico

- MP 299 Field

- 300 FSW

- Eight pile platform (210’ above water; 228’ long x 100’ wide)

- Crew Size: 20 Hydra Personnel

- Crew Disciplines

- Superintendent

- Foremans

- Welders Fitters

- Scaffolders

- Riggers

- Fire watch

- 7,287 man hours

- Zero incidents on platform

- Completed in 40 days

Taking Action

Safety was a primary concern. With multiple INCs issued by BSEE for a variety of reasons―including missing grating, holes in the deck and lack of safety gear―Hydra had to restore many aspects of the platform before any other personnel or P&A crews were allowed on the platform. Hydra also had to reconstruct the platform adequately and appropriately to safeguard Freeport-McMoran against further BSEE INCs.

In addition, although this field operated in the Gulf of Mexico for decades, it ceased operating several years ago causing the structure to become dilapidated. The well bays were over 50% corroded and, in some cases, non-existent. Before the P&A crews could execute their portion of the project, Hydra’s team had to strategically reconstruct the well bays on location. While the bays were more decayed than originally thought, Hydra worked efficiently to complete the rebuild.

“Hydra always completes great work for us. Ricky Garcia, a member of their team, is one of the best supervisors I’ve had overseeing these types of projects. When we were preparing, I specifically asked for him because I knew he was not going to get beat by the platform.” – Trey Savage, Company Representative

START YOUR NEXT PROJECT WITH HYDRA

TREVOR DAVIS, Project Manager | tdavis@hydraoc.com